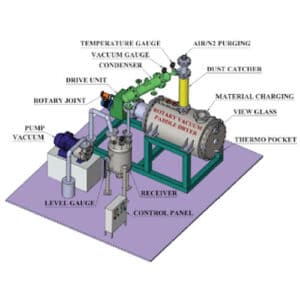

Product description

RCVD Salient Features

- GMP Unit, ideal for the Pharmaceutical, Chemical & Food industries.

- Good for powder/granules, free-flowing material.

- Drying at a lower temperature under vacuum.

- Good solvent recovery.

- Rapid and complete discharge.

- Closed system – Automatic charging & discharging.

- Provision of sampling port without breaking vacuum.

- Provision for Lump breaker.

- Provision for N2 pulsing & purging arrangement.

Rotocone Vacuum Dryer Product Range

- 100 Ltrs. to 10000 Ltrs.

Condenser and Receiver are optional according to client requirements.

Rotocone Vacuum Dryer Special Featured

- STAY PIPE DESIGN

In the earlier design of the RCVD spiral, stiffeners were welded on the main shell to strengthen the mail shell. The bulging of the jacket and main shell during the running operation was minimized due to the stay pipe design.

- GARLOCK SEAL (OPTIONAL)

Garlock seal design incorporated to eliminate the chances of the black particle from the vacuum pipe.

- STRENGTHENING OF THE SHAFT

To increase the strength of both side shafts, a solid round rod is machined which gives more rigidity.

- ROTARY SEAL DESIGN

A developed rotary seal design for better performance and economy.